Better Energy Performance

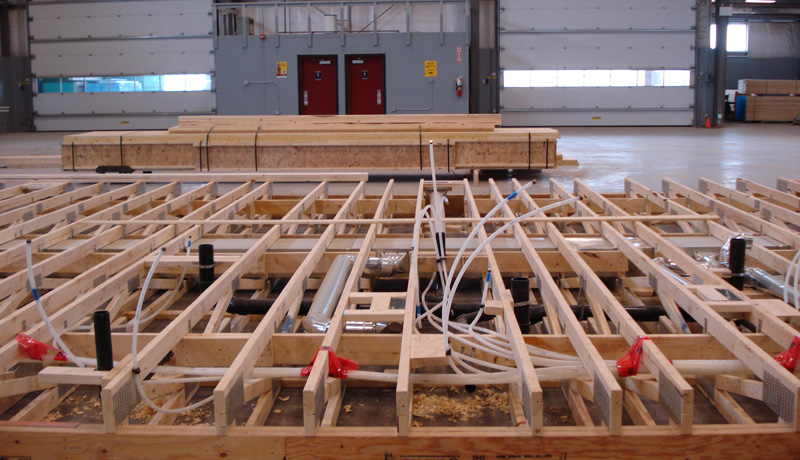

Climate controlled factory conditions and assembly line procedures optimize thermal insulation and air/vapour barrier installation, resulting in a tighter and better insulated envelope that requires less energy to heat and cool.

Reduced Environmental Footprint on Home-Site

Homes/buildings arrive at destination in one or more large modules that are 85% or greater complete. On site construction activity and time frame thereof is reduced by 80% or more, as is pollutants contained in heating fuels, toxic adhesives, other waste materials, and general impact on the surface environment and neighbouring properties.

Reduced Environmental Footprint on the Greater Area

The consolidation of labour and most building materials at the construction factory, usually within 150 KM of the building site, results in reduced car/truck traffic, noise, pollution and quality of life impacts, and in a shorter construction time frame than in areas where site construction of new homes and other buildings occur.

Reduced Material Wastage and Improved Disposal/Recycling

Manufacturing facilities purchase large quantities of lumber and other building materials, much of which is ordered to exact fitment requirements, there-by reducing waste. Waste that does occur is 50-70% less than when a building is constructed on site and can readily be recycled or disposed of properly.

Analysis of CO2 Emissions for On-site and Modular Construction

The residential construction practice of on-site wood framing has been widely applied in North America and has been considered to be a reliable, efficient, low-cost construction method for housing. However, the reality today is that technological innovation, higher costs, and the need for sustainable construction are challenging this method. In particular, there has been a significant increase in greenhouse gas emissions due to construction-related activities, and an alternative to on-site construction needs to be considered. In particular, the purpose of the following report, through a case study, is to compare on-site with modular construction practices in terms of their respective effects on CO2 emissions.

North Ridge CO2 Analysis Report – Comparison between Modular and On-Site Construction